A successful application of an engineering thermoplastic or thermosetting plastics are requiring more than identifying a specific product or grade. Three areas – design, product, process – are all interrelated and the appropriate rules in each area must be followed to ensure a successful application.Plastics specialists who need to explain their design decisions and the design limitations to non-plastics specialists.

Detailed plastic product design will always require detailed knowledge of the application, the processing method and the selected plastic.This information can only be provided by raw materials suppliers, specialist plastics product designers and plastics processors but there is a need to get the basics of the product design right in the first instance.

Using the hints and tips provided in this guide will enable designers to reduce initial errors and will lead to better and more economic design with plastics.

100 Hours

Introduction & Understanding About plastics

Introduction & Understanding About plastics

Properties of plastics

Properties of plastics

Classification of plastics and their application

Classification of plastics and their application

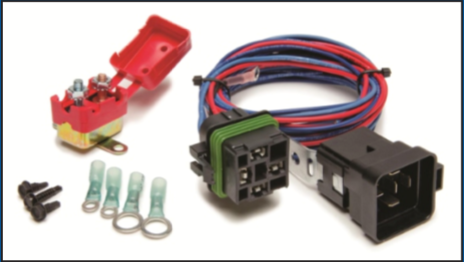

Types of manufacturing in plastics

Types of manufacturing in plastics

Plastic engineering

Plastic engineering

Aspects of plastic processing

Aspects of plastic processing

Geometry Considerations

Geometry Considerations

Mould wall thickness

Mould wall thickness

Draft Angles

Draft Angles

Hole placement,Ribs,bosses,gussets,snap fits

Hole placement,Ribs,bosses,gussets,snap fits

Living hinges, threads, grill.

Living hinges, threads, grill.

Design with any modeling software.

Design with any modeling software.

Certified instructors

Industry centric curriculum

Students will be offered with work book

Industrial based training

Industrial Certification

Opportunity for internship / placement assistance

Door No. 700/140, First Street Extension, Dr Rajendra Prasad Rd, Gandhipuram, Tamil Nadu 641012